How to Select and Use Kevlar Fire Wicks

Kevlar is a brand name for a high-temperature, synthetic aramid fiber. Other similar products are Nomex and Technora.

Kevlar was first used by Renegade Juggling to make fire torch juggling wicks in 1984. This material replaced the asbestos wicking used before it was known to be carcinogenic . At the time, asbestos wicks were reinforced with very thin wire because they were too brittle. Nowadays, Kevlar wicking does not require this reinforcing wire, although some jugglers still request it. Renegade gave the name of the new kind of wick "Kevlar Wick" which was adopted industry wide, though most fire wick is not actually made using the Kevlar brand aramid fibers.

Kevlar wicking for fire props

Below, we describe wick characteristics and some of the differences between the various brands.

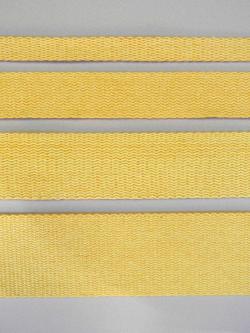

- The weave of the tape depends on the thickness, with twill being the best weave (see photo right, last two wicks on the right). If a strand burns or breaks due to abrasion, the fabric will not come apart. In contrast, if one or two strands break in a cross-weave (see photo right first wick on the left), the others will come apart as well. One should note that a twill weave is often not used in making 1/16-inch-thick material. It is better to use half as much 1/8-inch wicking, than twice as much of the 1/16-inch if it is made with a simple cross weave.

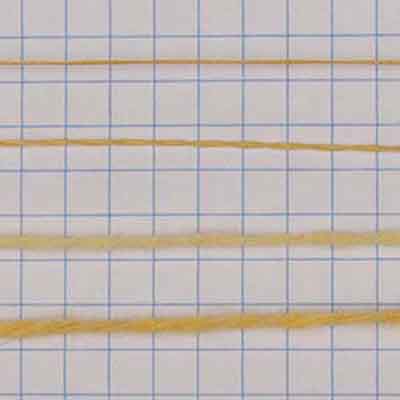

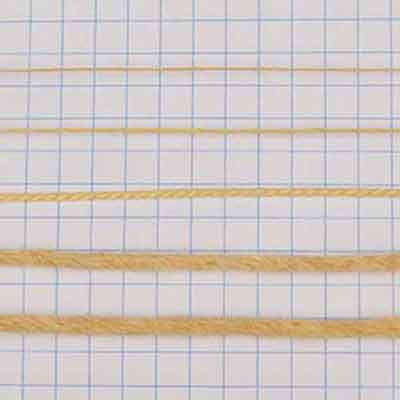

- The thread used to make the tape varies. There are many types of thread used to make kevlar wick. In the photo below is shown four types of thread that are typical for making wick. The top is fine pure Kevlar twisted pair, the second down thicker pure kevlar tiwsted pair, then spun pure Kevlar and bottom fiber core spun Kevlar. The kind of thread effects the density of the wick, abrasion resistance and how much fuel the wick will hold.

- The fiber core Kevlar thread wicking has a very tiny fiberglass core around which the Kevlar yarn is spun. This allows the thread to be more fluffy, but not break while is being woven on the machine. The more fluffy the thread is the more fuel it will hold. However the more fluffy it is the less abrasion-resistant it is. You can see from the photo that the thread has a wide range of thickness and texture, which is why kevlar wicking can vary widely on how it looks and performs. Each kind of kevlar webbing is defined by the thread type and weave type. You can see in the photo below how much of a difference there is between the threads, and how the spun thread has a much bigger diameter than the un-spun thread.

- Low-quality wicking has fiberglass (much cheaper and heavier material than Kevlar) blended into the yarn before the thread is made. When woven into wicking, the result is a much denser thread and a higher total weight. Furthermore, these fiberglass fibers cannot hold as much fuel as Kevlar ones. Often cheap wicking uses a low-quality cross-weave pattern, which allows it to be manufactured faster.

- Given that Kevlar is a brand name, cheaper wick manufacturers may use an aramid fiber that resembles Kevlar. If the wicking material fibers are made in China, they could have a lower heat-resistance than higher-quality brand name fibers. In making wicking material, the Kevlar thread accounts for about 60% of the cost. Since all weaving equipment worldwide is automated, the only way to make lower-cost wicking is to use inferior raw materials. There are other brands of aramid thread that has the same physical properties of Kevlar thread, most (if not all) Kevlar wicking is not made from Kevlar brand material as it is way overpriced.

- Technora is another brand of aramid fiber that has a much higher temperature rating of around 900F compared to 500F for Kevlar. Currently, Technora comes only in a rope form. It does not have good fuel absorption properties so it is used primarily as a leash material rather than wicking. All Technora products sold are made for the rope industry. Technora fibers have not yet been used for custom-made wicks implemented specifically in fire dance props.

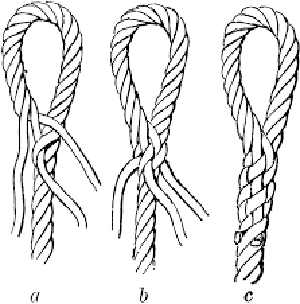

- Renegades Kevlar-based rope is made in two ways. The first type has an outer woven sleeve and linear strands of Kevlar wool that fill the sleeve or tube (see image below left). This construction allows the rope to hold a large quantity of fuel, but it is not strong enough to lift loads. Accordingly, it is meant to be used solely as a wick and not for load-bearing purposes. One can also utilize it as an insulation gasket. The second type of rope is a 12-strand woven rope that has continuous strands but no core (see image below right). This makes for a very strong rope but it does not hold as much fuel as linear core. As a result, this type of rope is better suited as leash material or for making props that have very high levels of abrasion.

Kevlar, Nomex, Technora, Twaron, and Abseil

These are some of the common brand names of heat resistant products, it could be rope, tape, webbing, cloth, firefighter gear etc. Each of these branded products has different characteristics depending on what type of fiber is used to make the thread and in turn the wick. For fire wicking the most important factor is heat resistance. Technora is has the highest 900F, Kevlar 500F and Nomex 300F. This is a approximate heat resistance as each of these brand names have different ratings, as they use different chemicals to make the fibers.

This has lead to lots of confusion in the fire dance or flow arts field, as people refer to the brand and not the fiber it is made from. In addition many manufactures do not use brand name fibers to make the products. For example virtually no manufacture of fire wicking, which we call Kevlar wick, actually used DuPont Kevlar, they use a cheaper generic non-branded aramid fiber and we call it Kevlar. Just like Kleenex it is a common name/brand. (Technora) poly-paraphenylene terephthalamide (PPTA), (Kevlar) poly-para-phenylene terephthalamide, (Nomex) poly-m-phenylenediamine isophthalamide are all are pretty complicated fiber names so it is no wonder why people use brand names. The term often used for all these types fibers is aramid. Which simply means, a man made organic polymer produced by spinning fiber from a liquid chemical blend... Pretty vague at best. When you buy wicking by name is really does not mean much you have too test it and see how good it really is.

But that issue aside, the main problem with using any of these aramid fibers to make fire wick is the heat generated while using the prop is way above the rating of the material. So all of these burn up, it is just a matter of how fast. Using higher temperature materials that can with stand the heat, like fiberglass or ceramic, do not have good properties, in regards to wicking weight, holding fuel or abrasion resistance. So fire performers are using a inferior material, the best option available, made out of somekind of aramid fiber.

Kevlar wick fuels

The type of fuel used has a large influence on the life span of the wick. With many kinds of fuel available, the most common ones fall into two basic categories.

- Kerosene is the primary component in lamp oil, tiki torch fuel, barbecue lighter fluid and airplane fuel. The advantage of a kerosene-based fuel is that it burns slower and at a lower temperature than Coleman white gas. It is not highly flammable and will not easily catch fire if spilled. However, it is harder to ignite at the start. The flame is more orange in color than a white gas flame and not as bright. Compared to white gas, this type of fuel will at least double the life span of the wicking material. It should be noted that cheaper kerosene-based products contain more impurities. The only pure kerosene product is airplane fuel. All of these kerosene fuels are toxic and must not be put in your mouth.

- White gas or Coleman camp stove fuel is very flammable and the prop can be easily ignited. It has a bright yellow flame. This high-burn temperature reduces the life span of the wicking material, and if spilled the fuel will instantly catch on fire. White gas in a vapor form is extremely dangerous and explosive. In the early 1980s to 1990s and before the invention of small propane cooking devices, it was a very common and cheap camping stove fuel, and thus became prevalent in the juggling scene. Over time, this fuel choice was passed along by word of mouth from jugglers to fire dancers. Although white gas does produce less smoke, it has more disadvantages than advantages when compared to kerosene fuels. Some performers add approx. 5% Coleman white gas to the kerosene fuels to make them ignite faster; the white gas burns off quickly and then the wick’s flame is fueled just by kerosene.

Fire Wick Q & A's

- What kind of fuel should I use?

The best fuel to use is barbecue lighter fluid, Lamp Oil, Tiki Torch fuel or Paraffin. All of these are just different names of kerosen. White gas, Coleman Fuel, gasoline all burn much hotter than a kerosen and will greatly reduce the live span of the wick. Many props require you use kerosen fuels as white gas will get to hot and burn the prop.

- How do I put out the flame of a fire prop?

Smother the flame when is starts to get low, in a 100% cotton damp towel or fire blanket. If you spin out or blow out the flame it reduces the life span of the wick. Always let the prop cool off between burns.

- Why do fire staffs need plugs in the end of the tubing?

If a fire staff is made from a hollow tube and there are no plugs in the end, the tube acts like a chimney. Hot gas get sucked into the tubing making it very hot.

- How do you cut the kevlar wicking, my scissors do not work?

Most household scissors are too dull to cut kevlar flat wick. Use a new box cutter knife. For cutting rope, wrap a ring of elctrical tape around the rope and cut at the middle of the ring with a box cutter. For the rope cutting use the box cutter knife like a saw.

- What size and length of wick should I get to make my fire prop with?

All props require different wicking sizing and length, just give us a call at 831 426 7343 and we can advise you what to get.

Kevlar wick fueling and Kevlar wick construction.

Fire props are made of some combination of flat wick tape or rope rolled/tied/woven around a core. Important factors to be considered when fueling and using the wick are as follows:

- The best way to fuel a wick head is to squirt on the fuel using a barbecue lighter fluid-type bottle. In the early 1980s to 1990s, it was common to dunk a juggling torch into a wide-mouth bottle and then shake out the excess fuel before use. This is wasteful and ecologically unsound. It is much better to apply the correct amount of fuel on the wick with a squirt bottle.

- For many uses, fire wick is wrapped around a shaft or some other inner support. It is very important that the Kevlar material is not too thick, otherwise it will burn on the inside of the wick head instead of the outside. Stopping combustion in the center is extremely difficult, even after the fuel is gone. This is why all monkey fist wick heads have a wood or tin foil ball in the middle. The wick should not be more than 2 inches thick to prevent internal combustion.

- Kevlar wicking is not sufficiently resistant to high temperatures to last forever. However, you can greatly increase the life span of the wick if you put it out while there is still fuel burning in the wicking material. As the prop burns down, you should smother the flame out ( do not try and blow or spin it out). Even if all the fuel is burned, the wick ends are still hot and the wicking material will continue to burn. After each use, allow the wicks to cool off. To obtain the longest life span, allow for sufficient cooling time between each use.

- When making a wick head, one often needs to sew the outside edge of the wick. This should be done using Kevlar thread or twisted cord, which comes in several thicknesses, with thicker being better. Do not use a running stitch. Knot off each stitch so if it was to burn through, all the stitching will not unravel. Wire, ideally foundation wire, is sometimes used to tie the wick to the prop. The problem with using wire is that it will get very hot and burn you on contact. Generally,contact with a burning wick that contains no metal will not cause a burn injury, or at least it will be much less than if metal wire or hardware are present.

Kevlar wick fueling and Kevlar wick construction.

Fire props are made of some combination of flat wick tape or rope rolled/tied/woven around a core. Important factors to be considered when fueling and using the wick are as follows:

- The best way to fuel a wick head is to squirt on the fuel using a barbecue lighter fluid-type bottle. In the early 1980s to 1990s, it was common to dunk a juggling torch into a wide-mouth bottle and then shake out the excess fuel before use. This is wasteful and ecologically unsound. It is much better to apply the correct amount of fuel on the wick with a squirt bottle.

- For many uses, fire wick is wrapped around a shaft or some other inner support. It is very important that the Kevlar material is not too thick, otherwise it will burn on the inside of the wick head instead of the outside. Stopping combustion in the center is extremely difficult, even after the fuel is gone. This is why all monkey fist wick heads have a wood or tin foil ball in the middle. The wick should not be more than 2 inches thick to prevent internal combustion.

- Kevlar wicking is sufficiently resistant to high temperatures to last forever. However, you can greatly increase the life span of the wick if you put it out while there is still fuel burning in the wicking material. As the prop burns down, you should smother the flame out ( do not try and blow or spin it out). Even if all the fuel is burned, the wick ends are still hot and the wicking material will continue to burn. After each use, allow the wicks to cool off. To obtain the longest life span, allow for sufficient cooling time between each use.

- When making a wick head, one often needs to sew the outside edge of the wick. This should be done using Kevlar thread or twisted cord, which comes in several thicknesses, with thicker being better. Do not use a running stitch. Knot off each stitch so if it was to burn through, all the stitching will not unravel. Wire, ideally foundation wire, is sometimes used to tie the wick to the prop. The problem with using wire is that it will get very hot and burn you on contact. Generally,contact with a burning wick that contains no metal will not cause a burn injury, or at least it will be much less than if metal wire or hardware are present.

Kevlar wicking burn time

The most common question is: how long will the wick burn? The burn time depends on many factors.

- Prop rotation speed. The faster you spin a prop, the more oxygen the wick head gets. It will therefore burn faster and consume more fuel.

- Fuel absorption by the wick. When the wicks are new, they hold more fuel than after repeated use. If the burn time is getting short, the wick needs to be replaced. The wicks can be washed with soapy water to remove some residue and this will slightly improve the amount of fuel absorbed. However, getting a new wick is the better solution.

- Wick thickness. The thicker the wick, the more fuel it holds. One should note that the burn time is not affected by the length, but by the thickness of the wick. For example, a 4-inch staff wick that is one inch thick will not burn longer than a 3-inch wick that is one inch thick. In almost all cases, fire props will not burn longer than about 5-7 minutes. If you want to burn a single strand of rope, it must be at least a 1/2 inch thick. Rope that is too thin will not hold enough fuel to burn any length of time and can be easily blown out. For example, to make a fire hoop that a tiger would jump through, you need to use rope wick having at least a 5/8-inch diameter. It will then have a big enough flame that will last a few minutes and not be blown out.

- Wicking thread. The wicking material can hold more or less fuel depending on how the thread is spun to make the wicking. Renegade wicking is made by spinning the Kevlar yarn around a very thin fiberglass core. This method creates a fluffier thread that holds more fuel than a pure Kevlar one.

- Absorption comparison between Renegade wick (fiber core thread) and Puro wick ( twisted pair 100 % kevlar thread ) Dry weight one foot 2 in x 1/8 in. Renegade 19.8 gram Puro 19.4 grams, statured weight Renegade 45.8 grams Puro 40.6 grams. The Renegade fiber core thread wicking hold about 12% more fuel. In theory it will burn 12% longer, however we did not do a burn test. There are other factors than simply absorbing capacity of the un-wrapped wicking

- Weave type and tightness of wick wrapping or braiding make a big difference in how much fuel the wick head will hold. The tighter the weave or the tighter the wrap on the prop, can reduce fuel absorption. The weaving or wrapping should be firm, but not so much that it is over tighten.

Kevlar wicks made with metal hardware or wire

Most fire dance props require the wick head to be attached to something. As with poi, it is attached to a leash or chain with the connectors usually made of metal. When the prop is burning, these metal parts can get very hot (much hotter than the burning wick surface). If you accidentally touch these metal parts, they will burn you. If you touch the actual wick, the risk of getting a burn is low to zero. For this reason, the amount of hardware and the exposure to it should be reduced as much as possible.

A safe and easy way to connect wicking to a prop is by using foundation wire (the wire used to tie re-bar in concrete). However, this wire will get very hot and will burn you on contact. This method is ideal if you are using the prop in a no-contact manner.

The best way to eliminate hardware is to make a spliced leash out of kevlar or technora 12 strand rope. It is a little hard to learn at first but lots of youtube videos on how to do it. This photo shows large eyelet size, but for poi leashes is can be made much smaller, and will cover the attachment hardware nearly completely

Kevlar wick sizes

Flat wicks come in many sizes. The most common size used in many props is 2 x 1/8 inches. This is good for making a folded poi wick; when placed side by side, one can also make a 4-inch staff wick. Short pieces are good for fire fans and other small props. A 20% discount is given when you buy the wick as a 100-ft roll. If you are unsure what size to try, this is a good starting point to make many kinds of props.

Kevlar rope also comes in many sizes depending on use. For making commonly used monkey fists, 3/8, 1/2 and 5/8 inches are typical sizes. Larger diameters let you produce larger knots. When using rope to make fire snakes, jump ropes, lassos, or fire swords, you need to use diameters of at least 5/8 inch or greater. The Renegade fire snake and jump rope both use one inch rope.

Colored flames made by adding metal powders to Kevlar wicks

The color of the flame can be changed by adding chemicals or metals to the wicks/fuel. This is not recommended as most of these combusted metals or chemicals are then released into the smoke, which you can end up inhaling. Inhaling smoke should be kept to a minimum anyway, and adding carcinogenic metals/chemicals to the smoke presents a greater risk to your health.

Fire breathing

Putting fuel in your mouth is poisonous. There is no safe way to have any fuel in your mouth, especially because it is carcinogenic. If you want to have a fire blowing effect, never use gasoline or kerosene-based fuels. Use powders like custard or lycopodium powder. Even high-proof alcohol like Bacardi 151 can damage the membranes in your mouth. Fire breathing is a magic trick, where the audience is tricked into thinking that you are spitting flaming fuel, when in fact you are blowing powder from a tube in your hand. Using your mouth to extinguish a kerosene- or white gas-based flame is not safe.

Cleaning fire props with Kevlar wicking

It is important to clean your fire props after each use.

- Many fire props have a shiny or reflective surface combined with the wicking. If you do not clean this reflective material, it will become black with soot and absorb heat rather than reflect it. Soot that is not cleaned off can result in an unexpectedly hot prop.

- The soot from burning petroleum products should not come in contact with your skin or eyes. If the props are cleaned after each use, you will greatly reduce your exposure to these by-products.

- Many props use a silicon cover for insulation against heat. When this is burned, it produces silica dioxide. This powder along with the soot should not come in contact with your skin or eyes. Clean all these silicon surfaces after each use.

- Always use covers on your wick heads when not in use. During transport or when practicing, use covers to prevent soot from getting on your skin and into your eyes. Socks work very well for this and can be washed or thrown out after becoming excessively soot-saturated. Lightweight gloves are also good for practice sessions to keep your hands clean.

Clean props reduce your exposure to toxic compounds. Play safe. Remember to always clean your fire props and wash your hands after use. Baby wipes come in easy-to-transport dispensers and are ideal for cleaning up after each fire session.